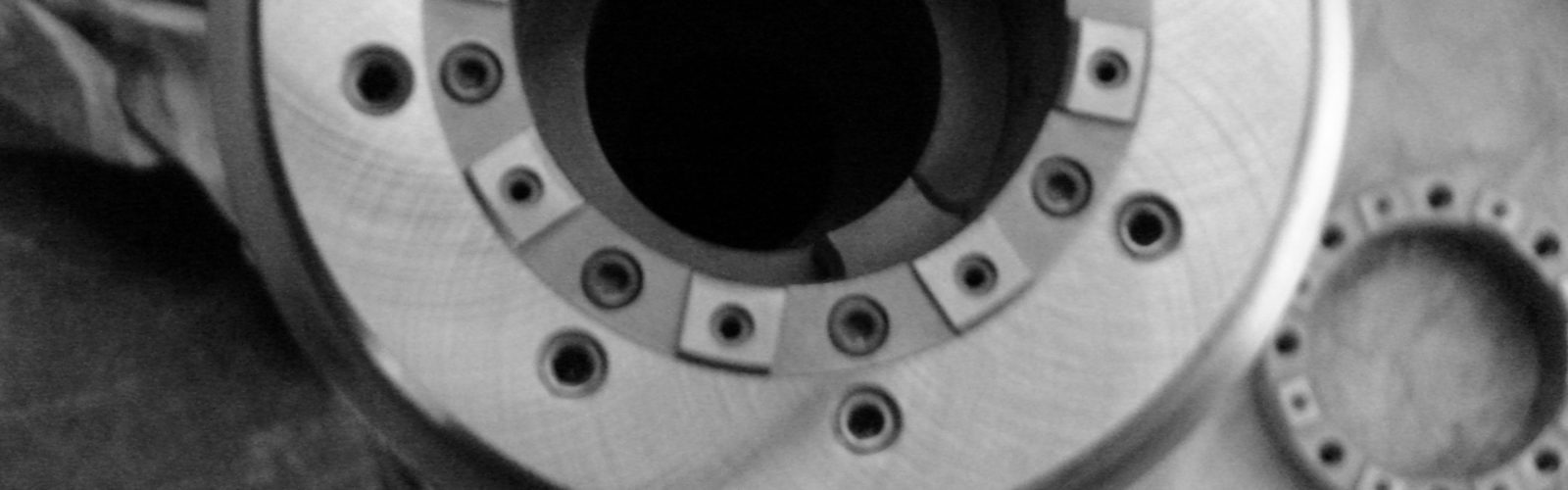

Taper grinding

PSG prides itself on the quality finish and execution of our taper grinds.

We can provide the following services (some being the same day turnaround)

- Grind tapers

- All internal and external tapers including

- International

- HSK

- Morse

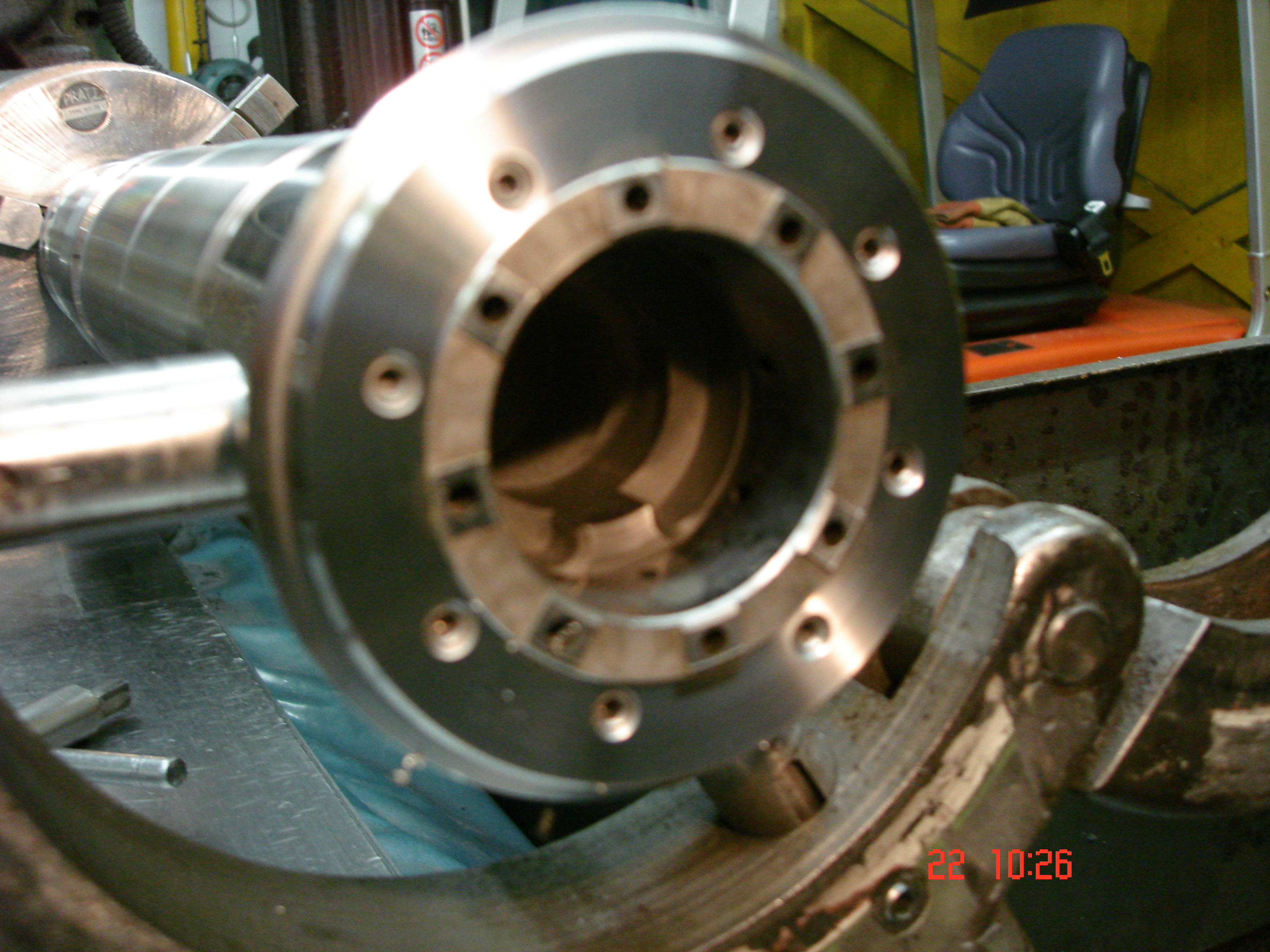

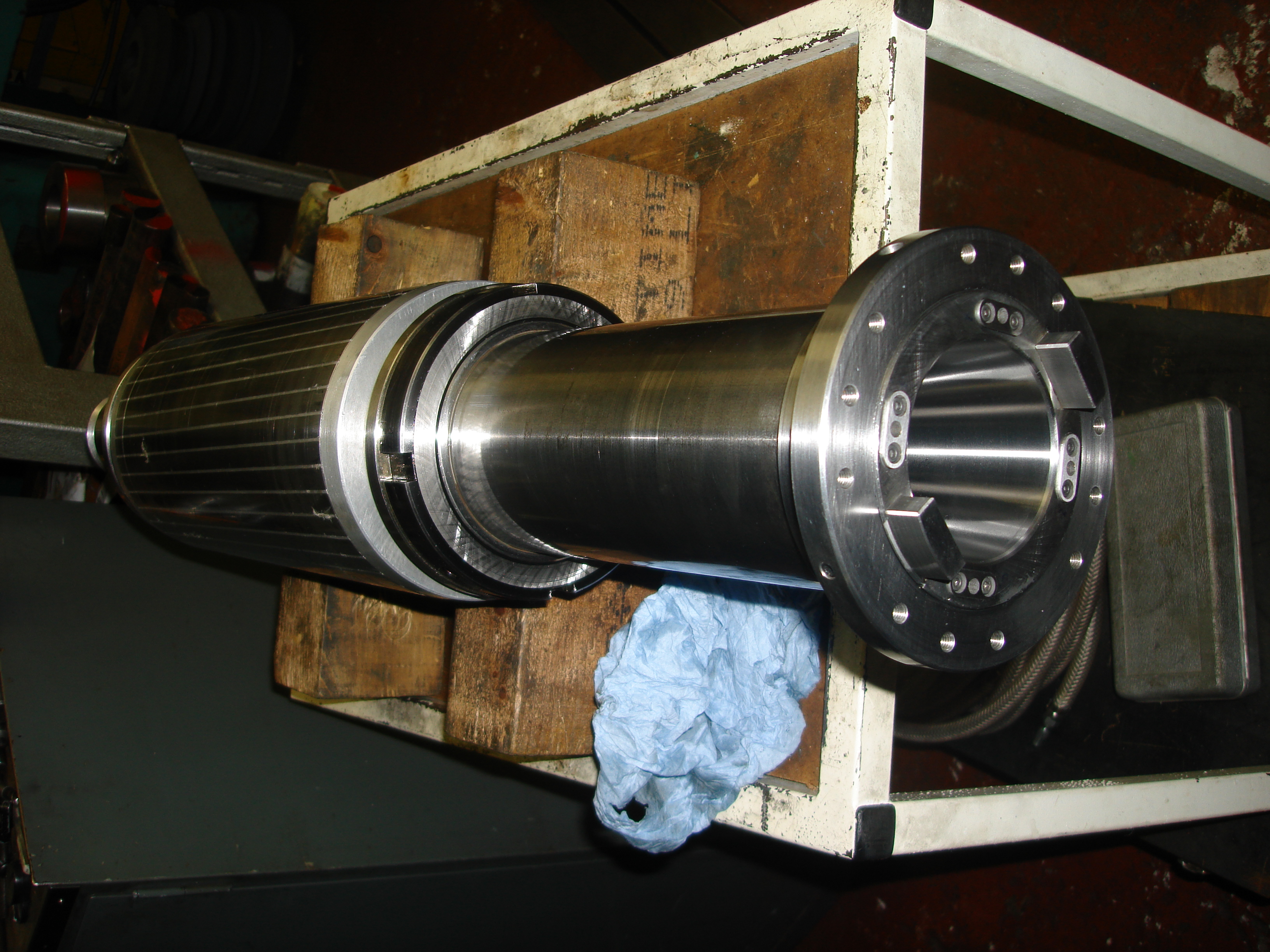

- Spindle cartridge assemblies ground in taper

Grinding spindle assemblies can be ground and wheel arbour bore can be cleaned up to maintain minimal run out.

See our images that showcase some of our work.

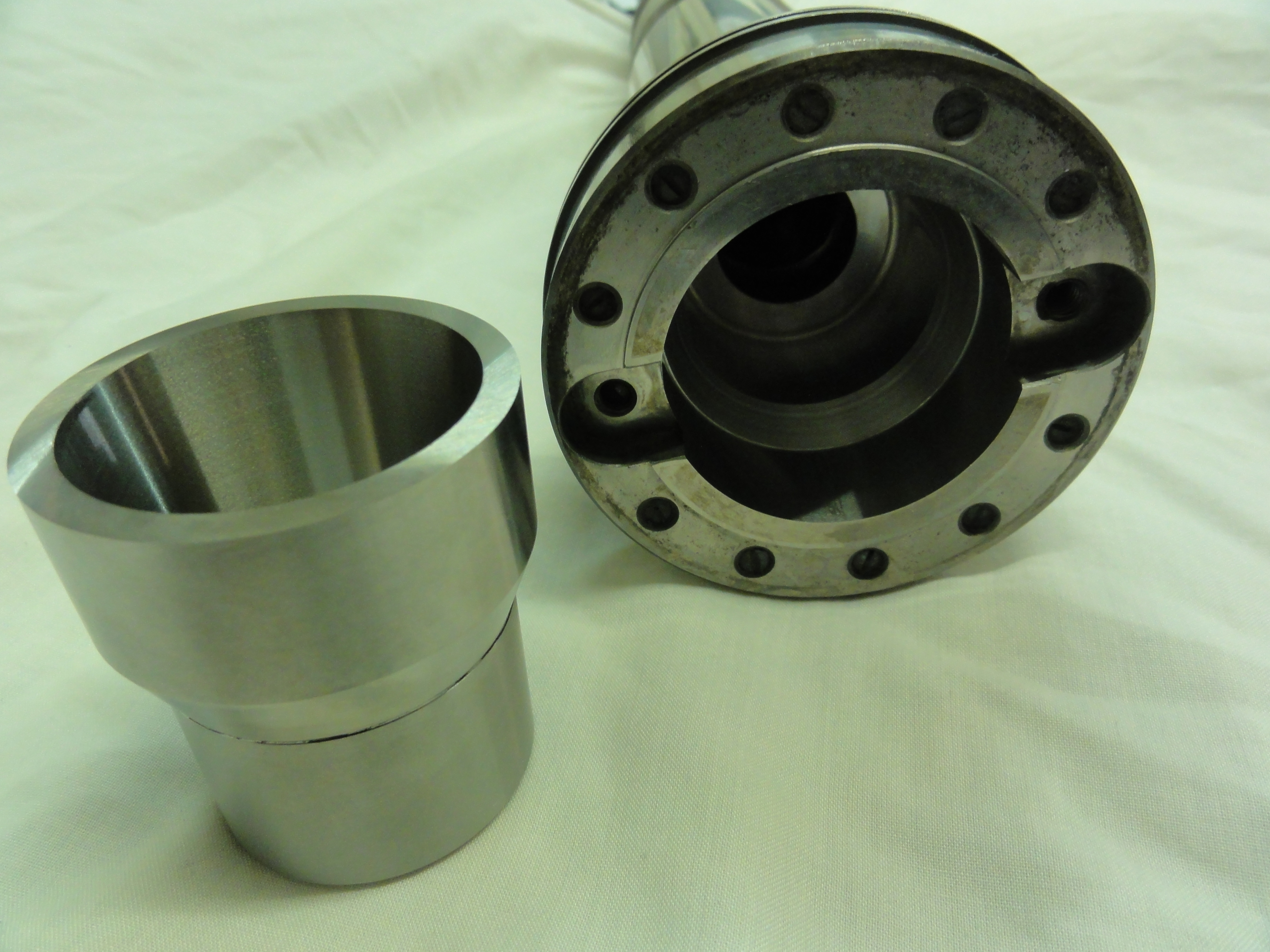

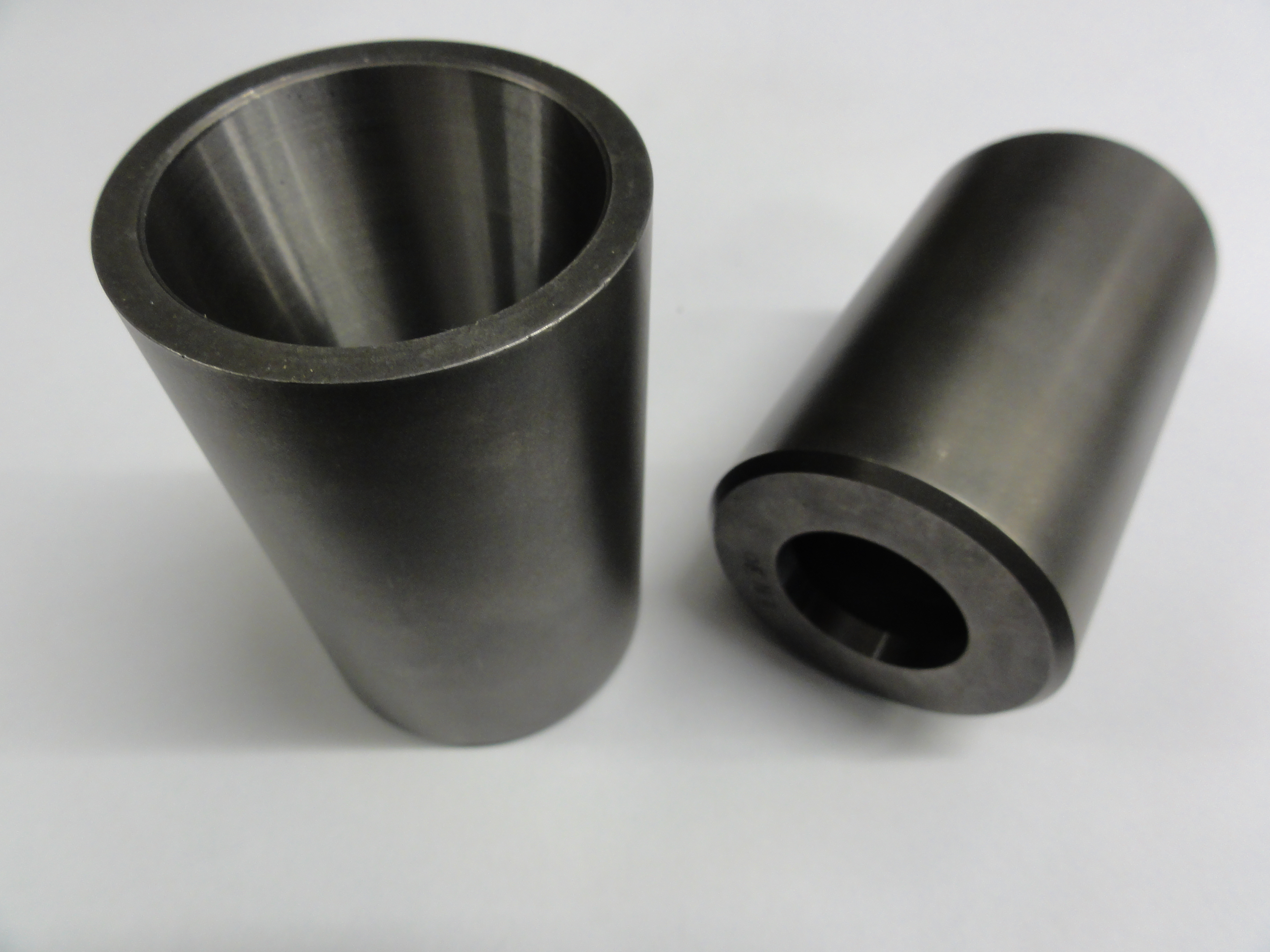

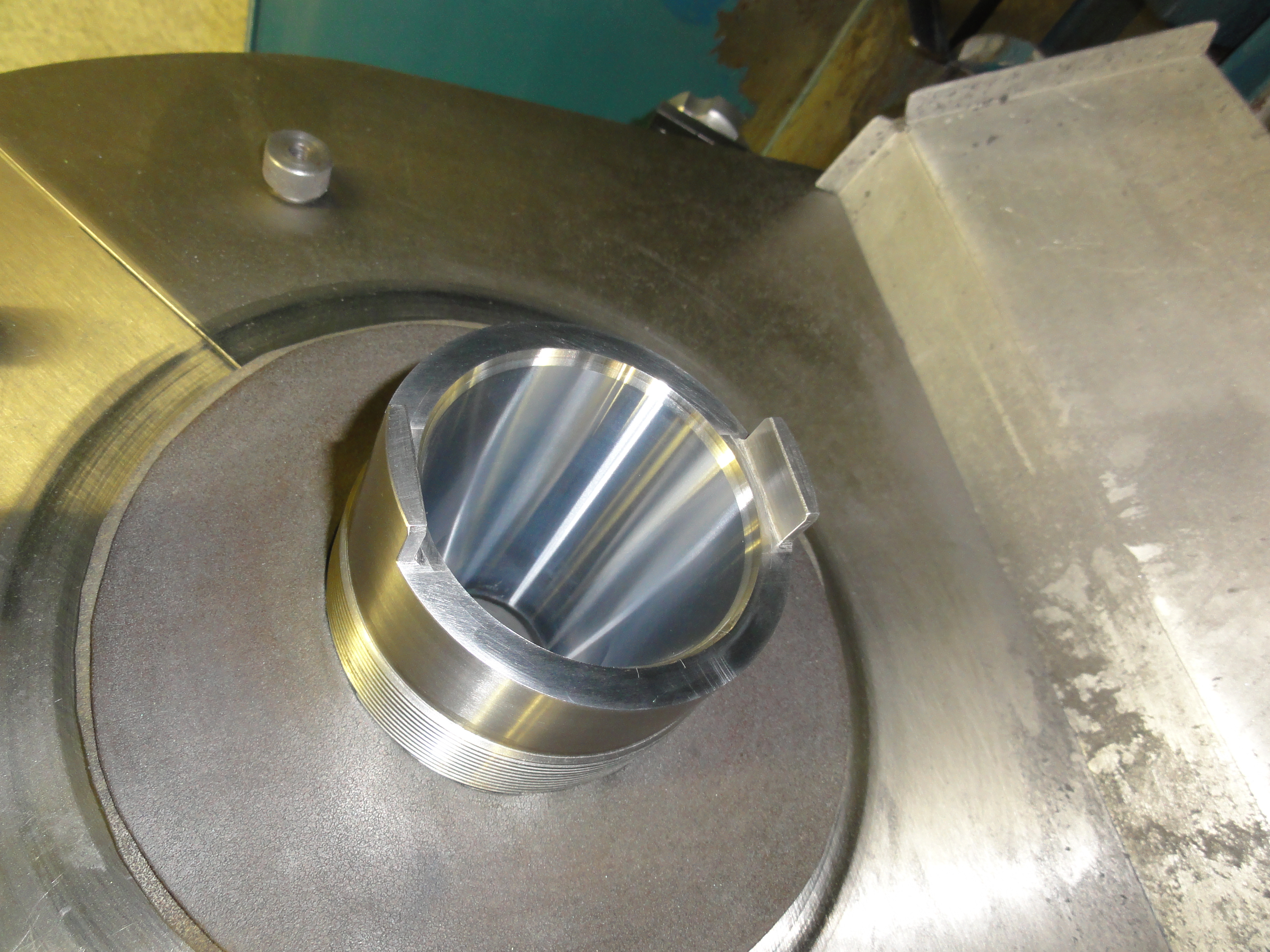

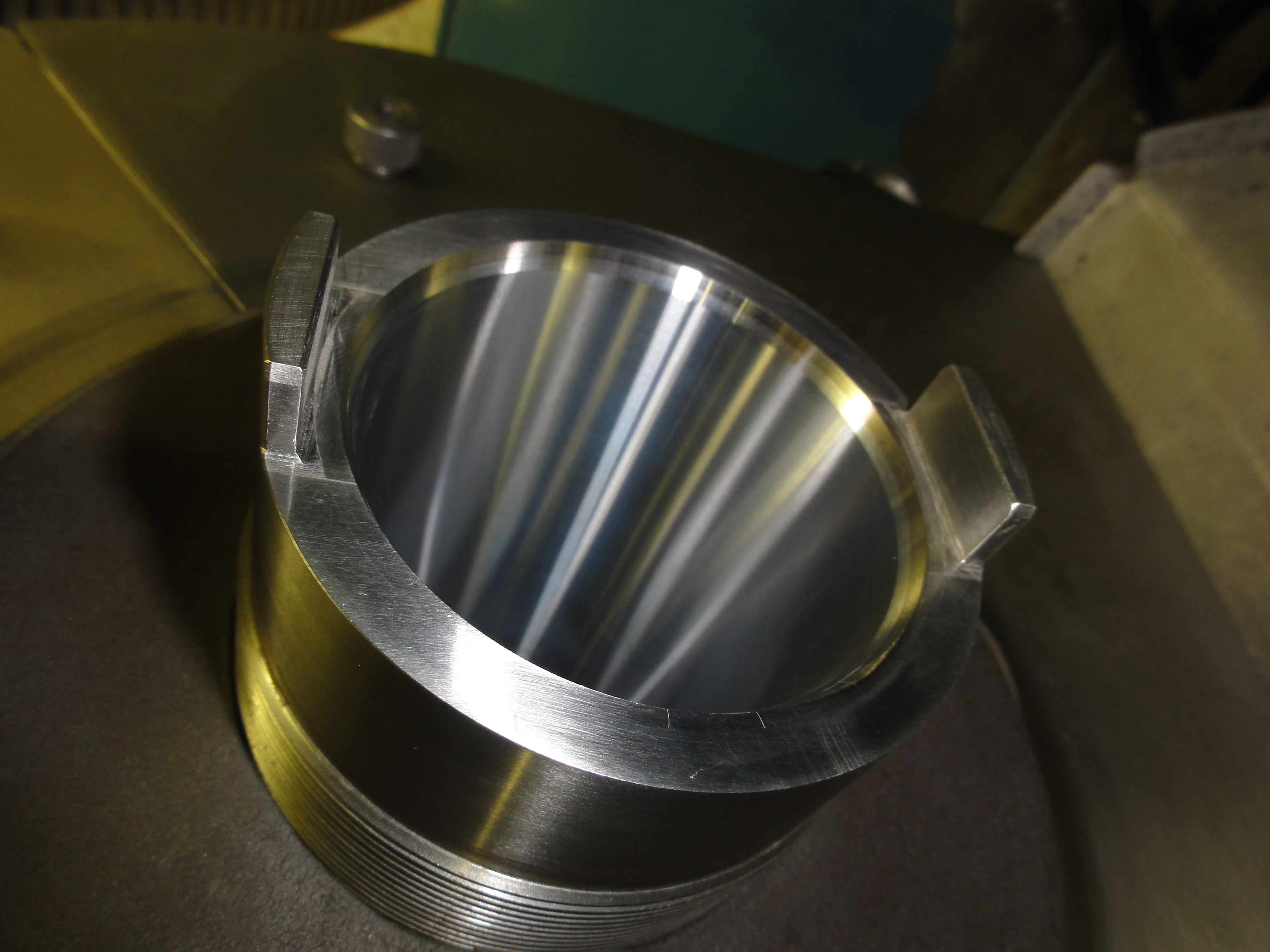

Bush Tapers

We are renowned for our precision when it comes to bush tapers, we are extremely knowledgeable and highly competent using a variety of materials to match your requirements as seen below in our gallery.

We also keep standard bushes in stock, contact us for information.

BT Stepped Bush

HSK 63 Brush With Air Purge

50 INT Bush

Standard bushes – IN STOCK

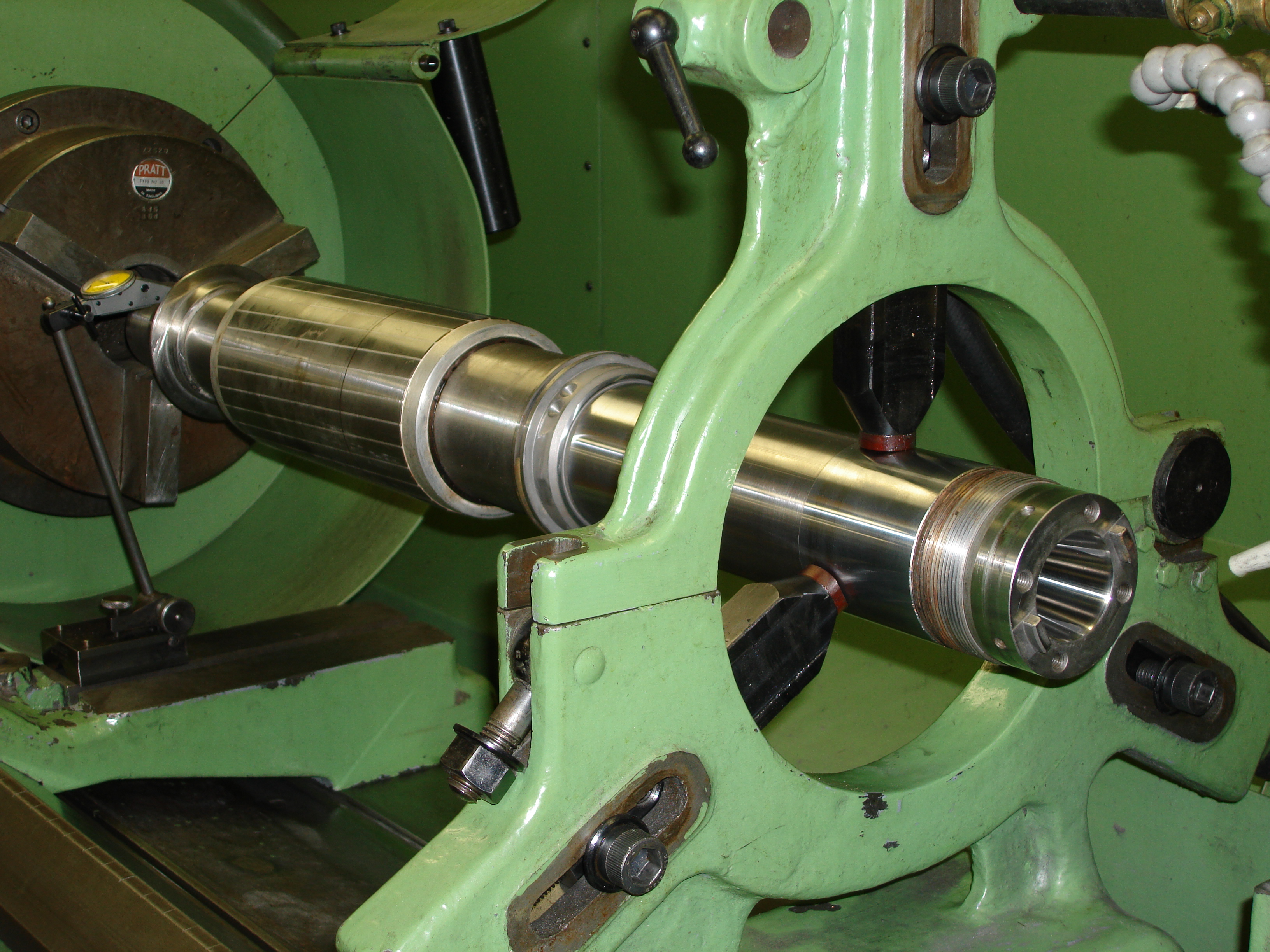

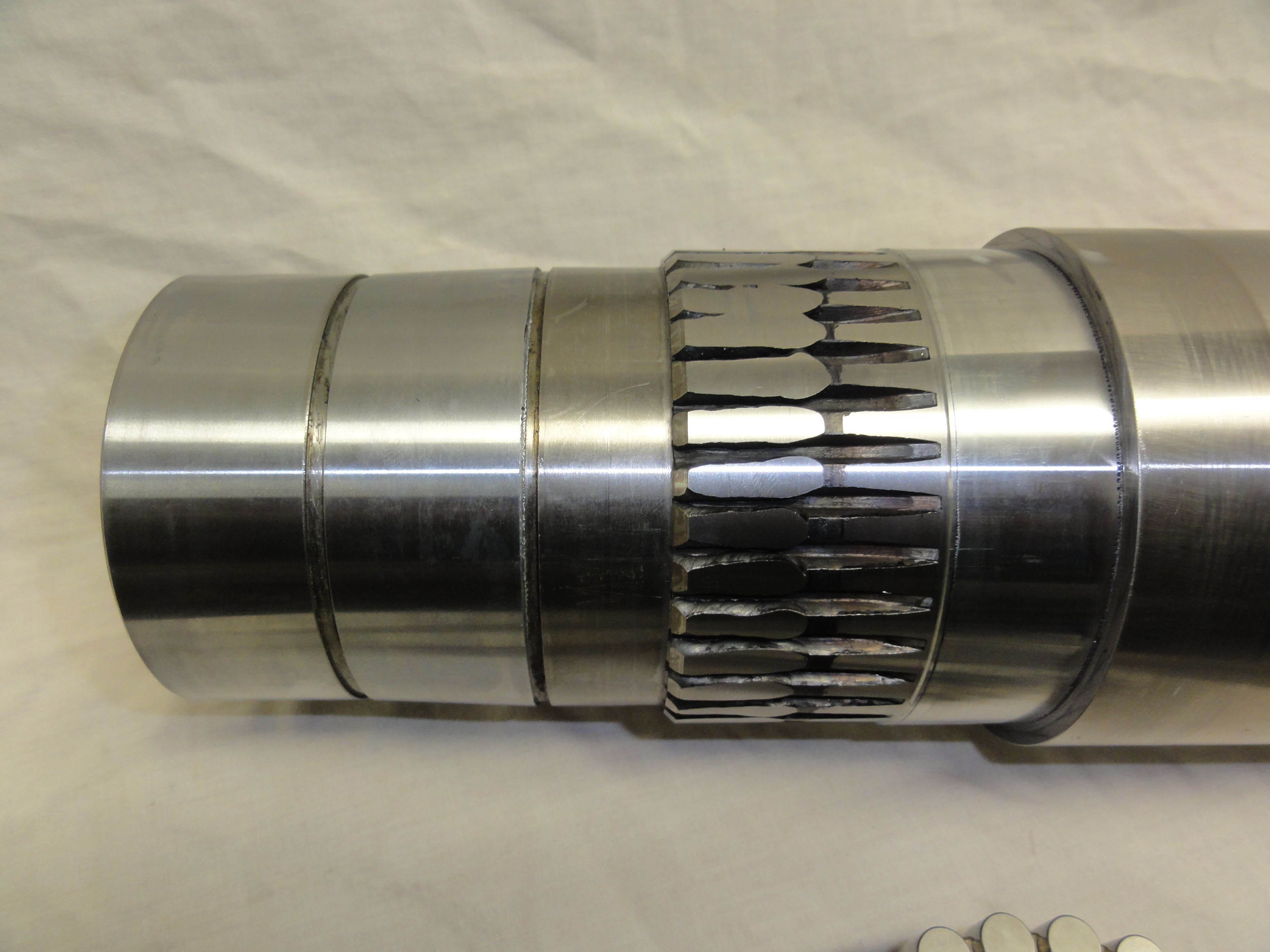

Repair Journals

Here are some examples of the work we have completed for customers.

Pulley bore ground out to clean up, pulley diameter on shaft has been ground and chromed, then ground to give correct fit.

Spline on shaft had been very badly worn. To repair shaft a complete sleeve has been fitted to rear and then been machined back to its original condition.

The front and rear bearing journals have been chromed and ground to correct sizes.

Gear journal, spacer diameters and NN bearing journal have been ground/chromed/ground back to original sizes.

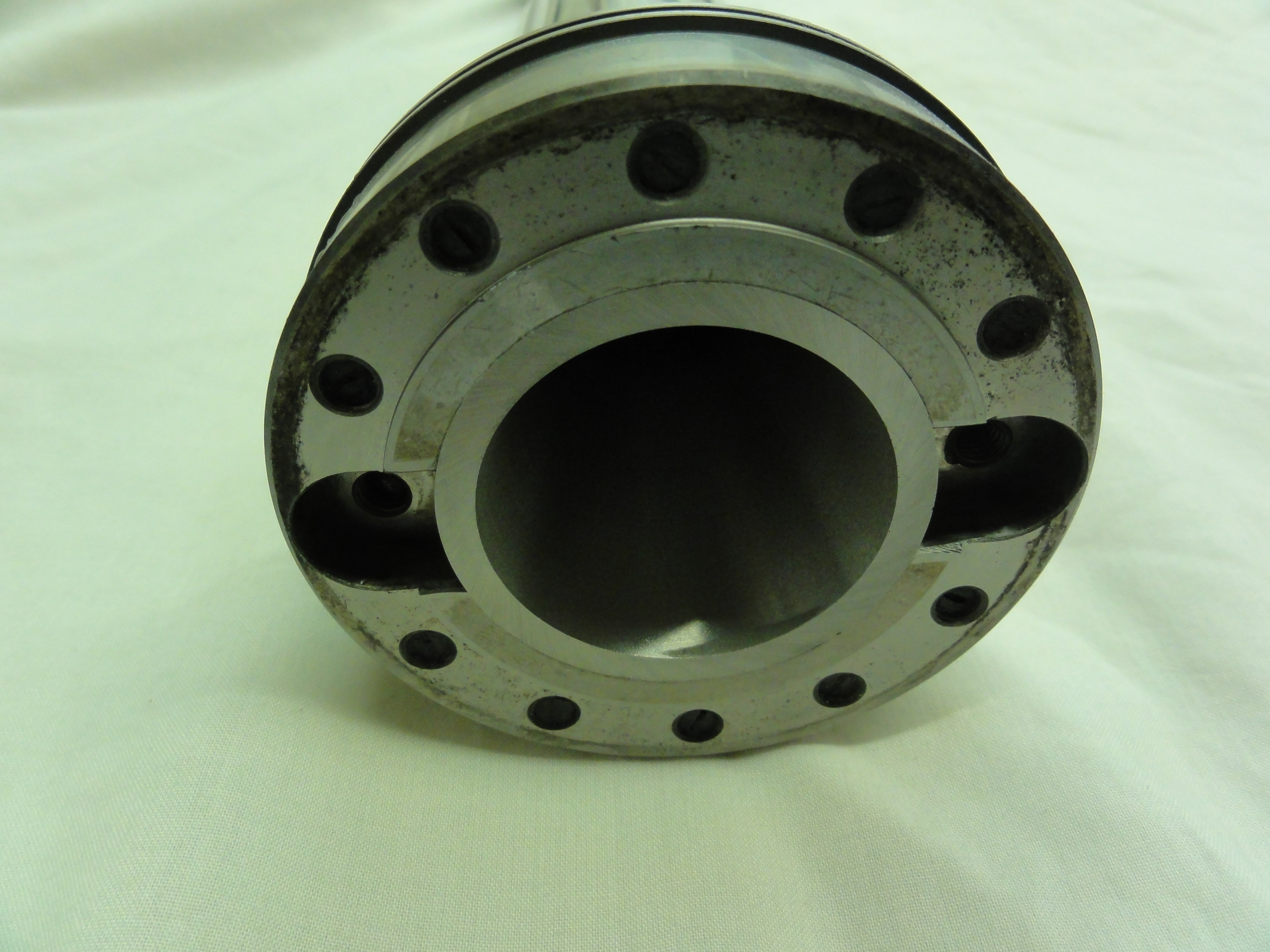

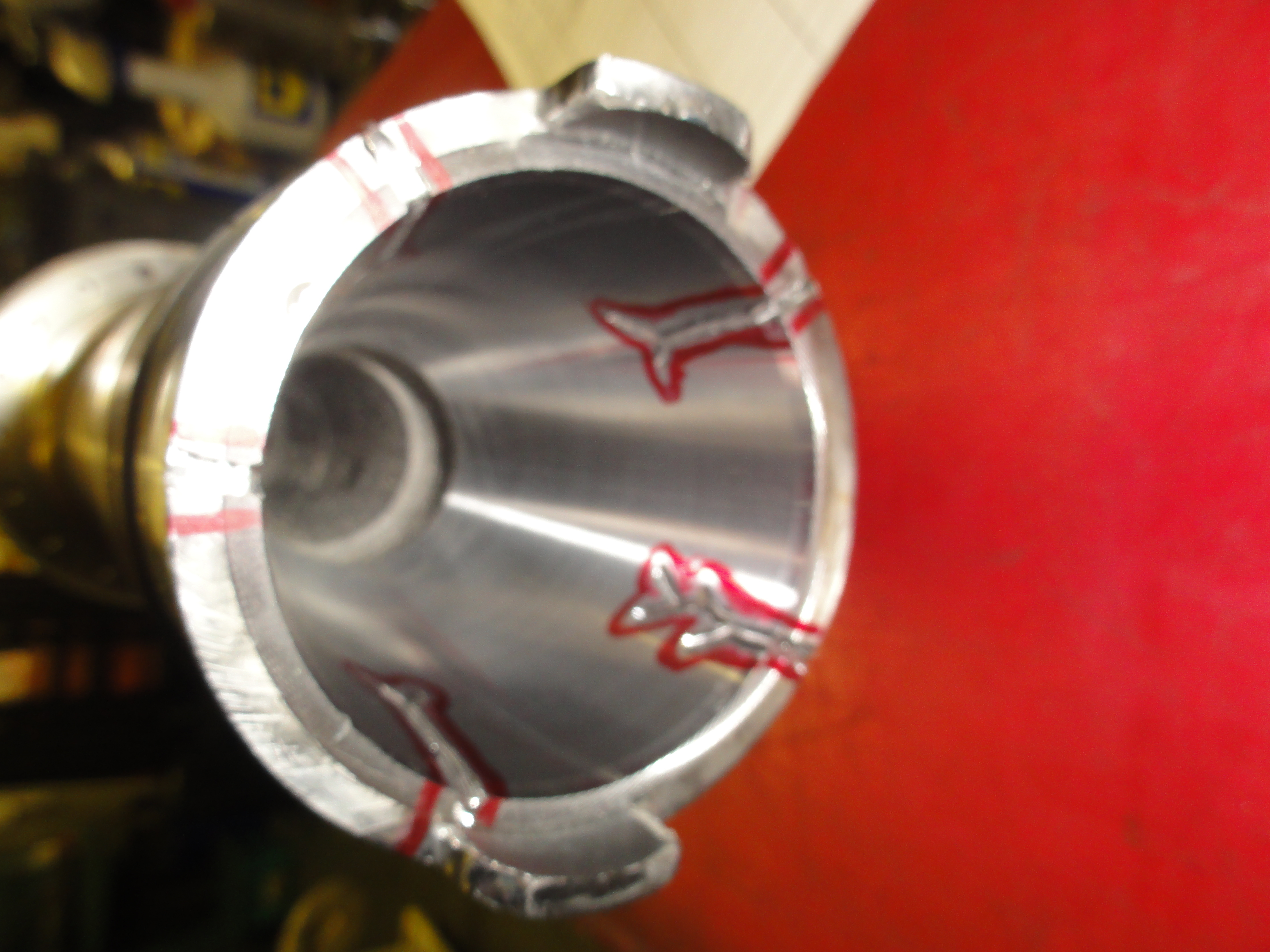

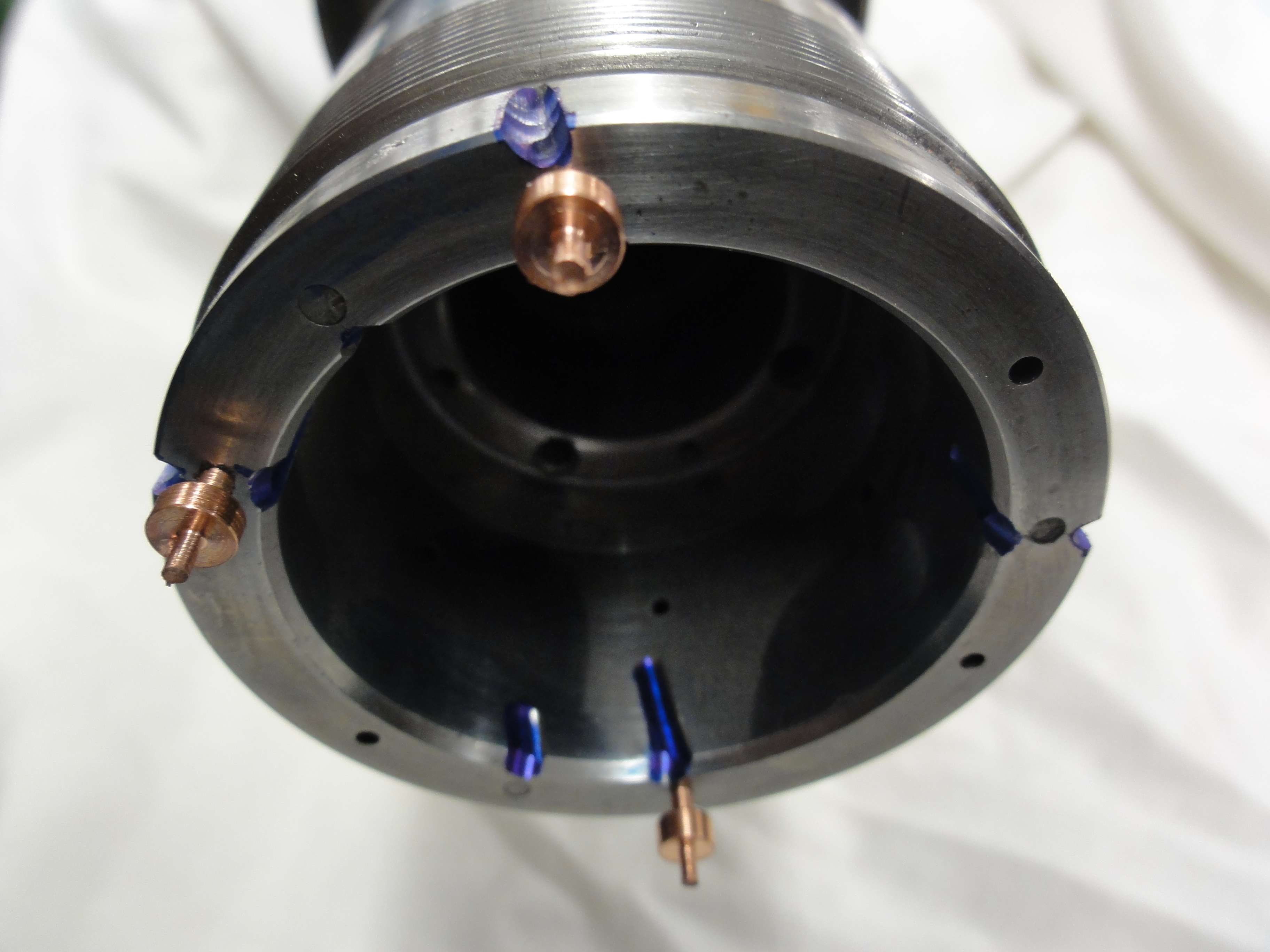

Repair Cracked Spindles

Here are some examples of the work we have completed for customers.

Spindle has severe cracks, once detected they are prepared for welding, weld is then ground away and taper is chromed & ground.

The spindle has air purge holes on front face copper pins are inserted to stop holes collapsing when welded.

HSK63 spindle prepared for welding.

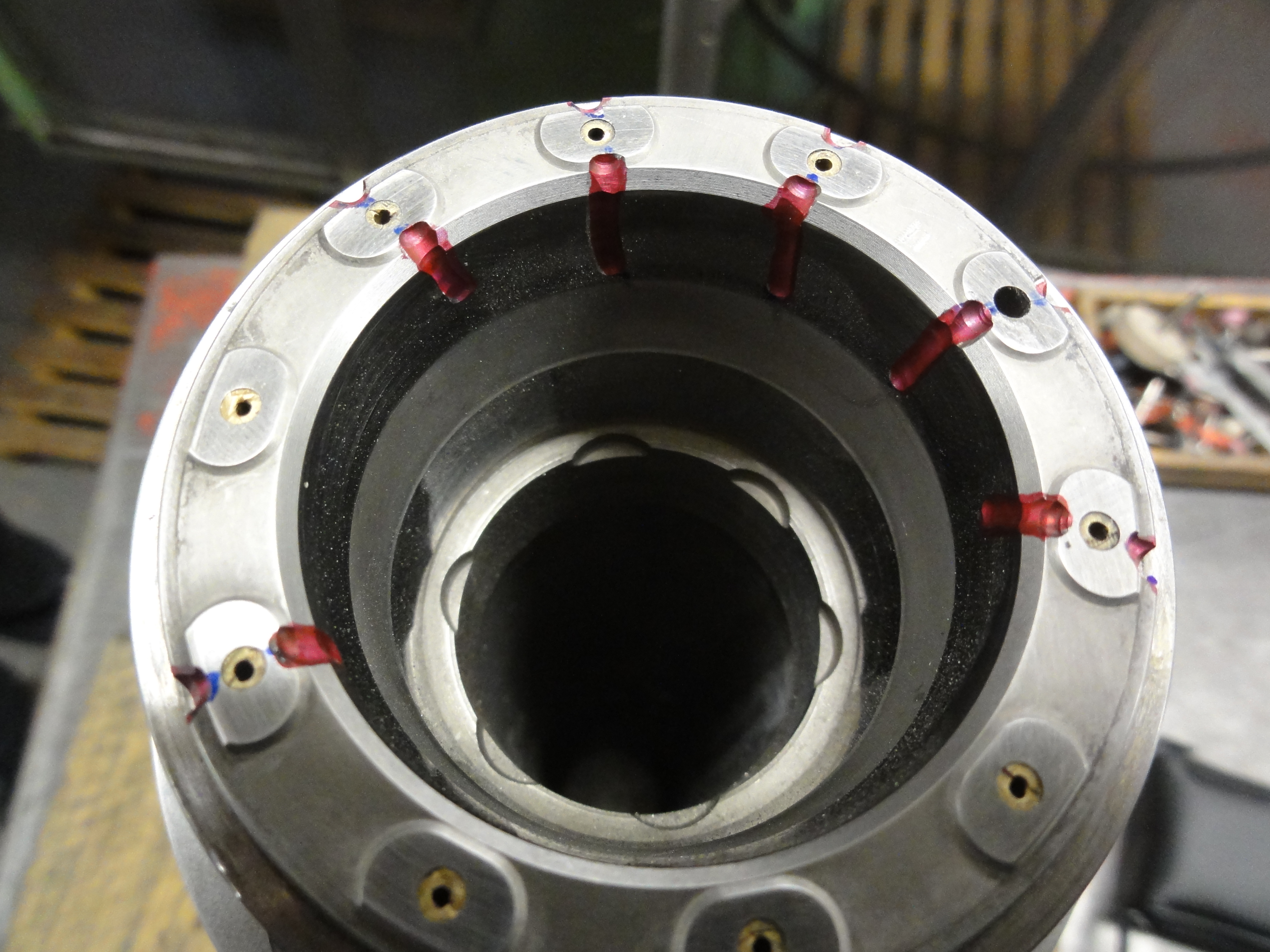

Drive Dog Repairs

Here are some examples of the work we have completed for customers.

The spindle has had its drive dogs smashed off, it has been re-engineered and new drive dogs to specification have been produced.

When drive dogs have been worn they can be hard face welded to 62 Rockwell and re-machined.

Worn drive dogs have been welded and ceramic bush replaced.

We are fortunate to have our own in-house welding facility within the factory.

Big+ faces

Here are some examples of the work we have completed for customers.

The first video shows a big+ face being ground out at premises.

The second video shows a big+ face being checked with a gauge.

40 INT taper/Big+ Face

50 INT spindle with Big+ pads